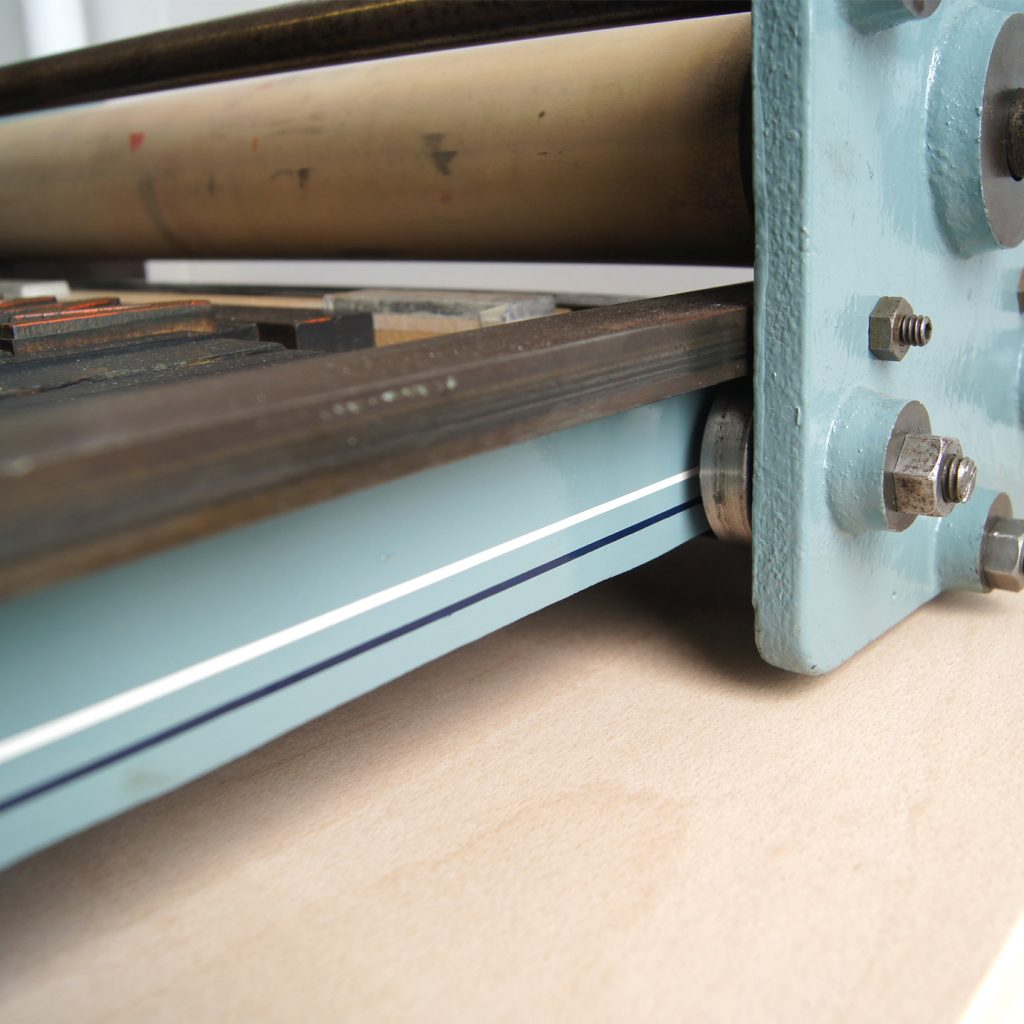

George Pallister & Sons Table Top Proofing Press

A simple straight forward hand ink push and pull proofing press. Always a joy to use as it is so basic and simple you can really feel the bite of the type on the paper when pulling a print – I find myself regularly lugging this large heavy press to fairs and running workshops up and down the country to let people have a go. When restoring this press I liked it so much that I gave the press “go faster pin stripes”.

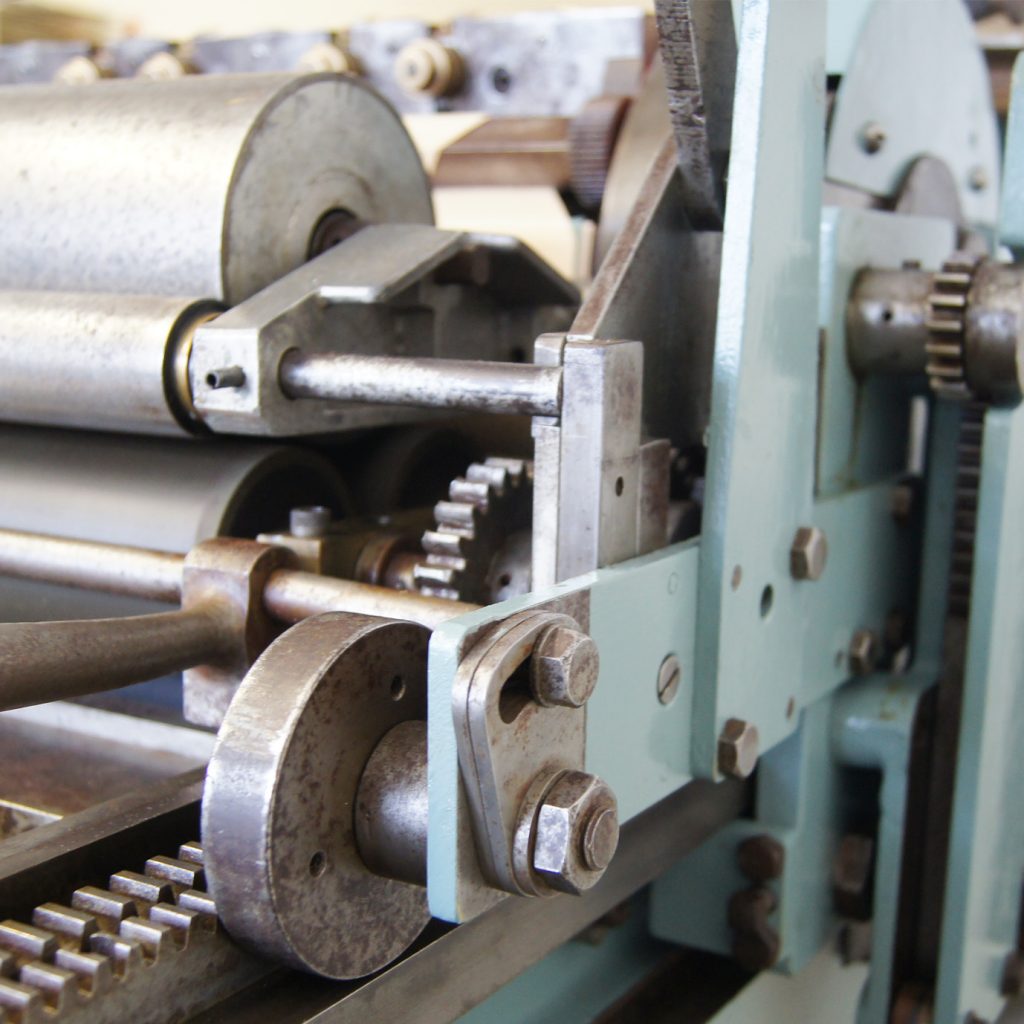

Vandercook 4C ‘the Brit’ Flatbed Cylinder Proofing Press

Built by Western Manufacturing (Reading, UK) in around the 1950’s I came to own this fine machine about 2 years ago after being contacted by a chap (Andy) I met at a trade fair several years earlier (Andy) – had owned the Vandercook for a number of years and had planned to restore it but did not have the time so the Vandercook had sat in a barn on a farm for many years waiting…. Andy offered me the Vandercook under the proviso that I restore it to its former glory, use it and enjoy it – a gentleman’s agreement was struck for Andy to come and have a go printing and for me to buy him a pint as a thanks after it was finished.

The Vandercook remains my largest restoration piece to date weighing in at over a tonne with many complicated delicate parts. The entire machine had to be stripped down, de-rusted and re-built. The only new parts that had to be sourced were a new custom motor and gear box, drive chain and some industrial steel cable housing, all the other parts are original.

Cropper Charlton Peerless

The Peerless is a foot powered treadle platen printing press with a clamshell style mechanism made in around 1890’s – 1910’s. These printing presses print one colour at a time, the paper has to be fed into and removed from the machine by hand at speed, whilst standing on one leg powering the press with the treadle pedal. Presses like these are commonly referred to as jobbing presses as they can be used to do any job. Early adverts for the Peerless claimed they “run as easy as a sewing machine” not having much experience with sewing machines I can’t really comment. I am the proud owner of three Cropper Charlton Peerless two Model No. 2 (7”x11” print area) both an early model and the later ‘improved’ model and 1 Cropperette 8”x5”.

Ideal Guillotine

As a collector of vintage printing machines, when I saw this 1967 Ideal 52e guillotine for sale on eBay only half a mile from my home I knew I was going to have to have it. It came in very poor condition but did come with a surprise printing press, some type and other bits which were a real bonus. The guillotine needed a fair bit of rewiring and a lot of cleaning down and resetting before its face lift but now works as good as new and is a great member of the team.

ADANA

Adana Printing presses were manufactured from 1922 aimed at the hobby printer in the pre-desktop pre-digital age, they really were the original desktop home printer. Adana are best known for producing the now legendary 8×5 press, known for being built to last and nearly indestructible, there are still lots of second hand presses available today and are still used in many commercial print workshops often being used for creasing or die cutting short run jobs.

The Adana is how I got started on my journey with letterpress – my first real letterpress purchase was a Adana 8X5 on eBay (when eBay was a new thing!) My early commissions started with one of these fine presses then I decided to expand and go big. I still use my collection of 7 Adana’s for demo’s, teaching workshops and pop up events.

MANUFACTURER UNKNOWN !?

With machines of this age (1890’s – 1900’s) you sometimes find that you don’t know and cannot find out much about them as sometimes there is not a manufactures mark – this is one of those cases. The press is foot powered (like the Whitefriars and the Peerless’s) and its party piece is that instead of a rotating disc for an inking plate this press uses an agitating cylinder / drum (like the Vandercook). This means that I can print with a ‘split fountain’ (different coloured inks are applied at either end of the drum and the agitation of the drum allows the ink to blend together causing a 2 colour fade) The effect is sometimes hard to control as the ink has a tendency to drift, meaning the colour shift evolves as you print.

WHITEFRIARS

This Whitefriars press is an unusual one, with all the other presses I own that are similar you alter the pressure of the printing press behind the plate area (4 bolts are behind the plate where the paper is placed) with this machine a completely different solution was found, the pressure adjustment is behind head area of the press (under the inking plate). Part of the joy of owning and operating machinery of this age is finding the love and attention to detail and the desire of real engineers to find new innovative solutions, when considering the era of manufacture this always amazes and delights me.